1. The crushing and shaping integrated machine has large feed size, adjustable output size, reasonable grading of finished materials, changing from three-stage crushing to one-stage crushing, one-breaking forming, no need for two-breaking, reducing equipment investment by 35%.

2. Changed the previous method of controlling the size of the discharged particles by using a wrench to adjust the bolt size. Large pieces of material actively avoid, reducing equipment damage, reducing the wear of the hammer in the crushing cavity, and ensuring the life of the hammer. Increase 4-6 times.

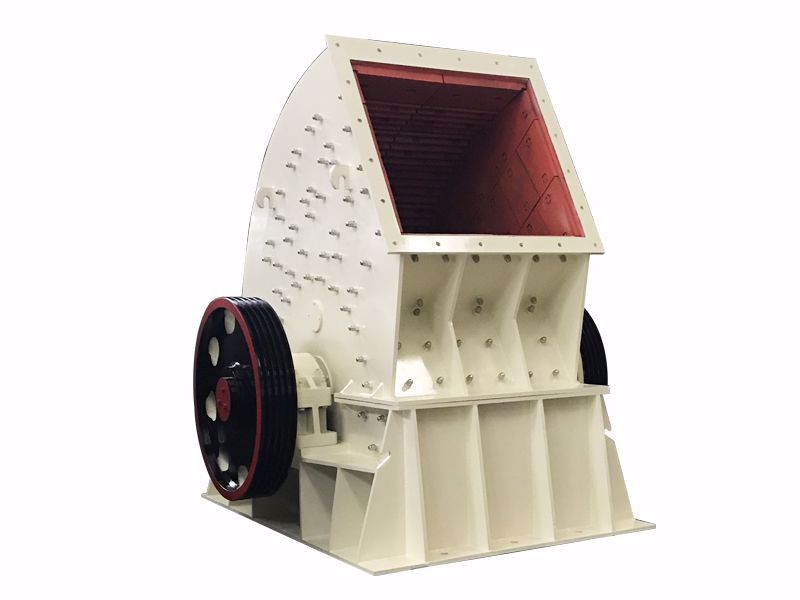

3. Snail shell design, back ribs, strong internal and external impact resistance, strong and non-deformed casing, excellent wear-resistant parts, manganese-chromium alloy hammer head, long service life, linings all over the crushing cavity, wear-resistant edge protection Protect the hammer from breaking, and the hammer plate is forbidden for a long time.

4. Eight-way hammer shaft holes, four-way standby, multipl